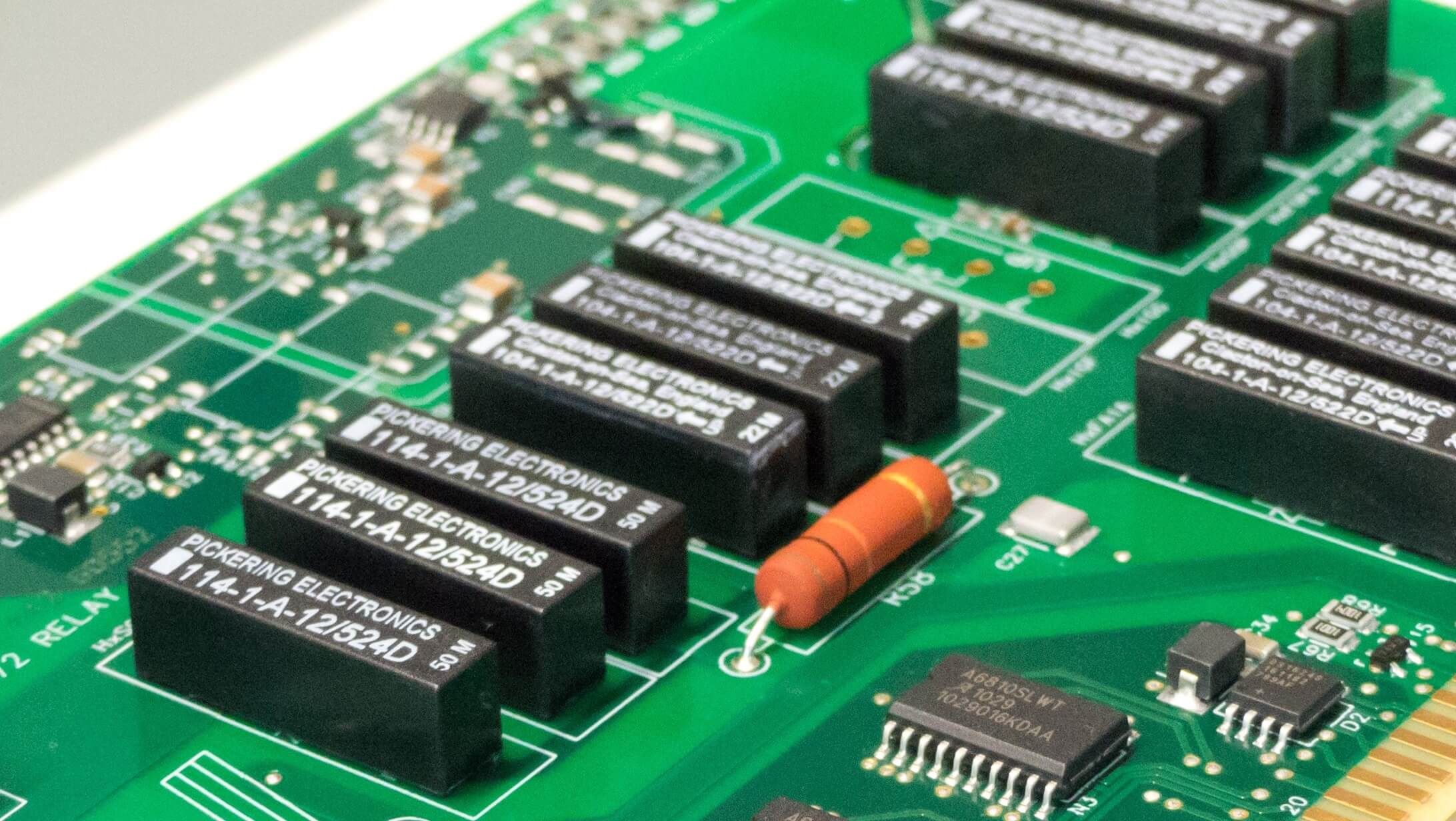

Military Pcb Assembly - Vital Systems offers 36 years of experience in printed circuit board (PCB) assembly. Over the years, our fine-tuned processes enable us to deliver high quality functional boards, out of every 100 "untested" PCB modules, 99 will pass electrical tests immediately upon shipment. The remaining 1% fail due to a combination of bad components or assembly problems.

Vital Systems has extensive experience assembling large, small and complex printed circuit boards for military and commercial applications. If needed, we design custom equipment for projects like this 3' x 4' PCBA.

Military Pcb Assembly

Our specialty is the assembly of densely packed printed circuit boards for high frequency and digital applications. Combinations of these technologies are commonly used in military equipment and video processing equipment.

The Complete Guide To Defence Electronics And How They Are Changing Lives

The RF filters, BGAs and QFNs are assembled to IPC-A-610 Class 3. A strict standard for spacecraft electronics or high-reliability military applications.

NASA, military and aerospace companies require the highest quality electronic modules. In 1986, the US Navy certified Vital Systems to assemble weapons electronics for military and space applications. This certification has helped Vital Systems win many defense contracts. Today, we continue to set quality standards that our loyal customers have used for decades.

Vital Systems assembles small PCBAs as small as 0.25 square inches (6 mm x 6 mm) for use in cameras and various IOT devices. We build thousands of them. Each of these small PCBs is programmed and tested before being shipped to customers.

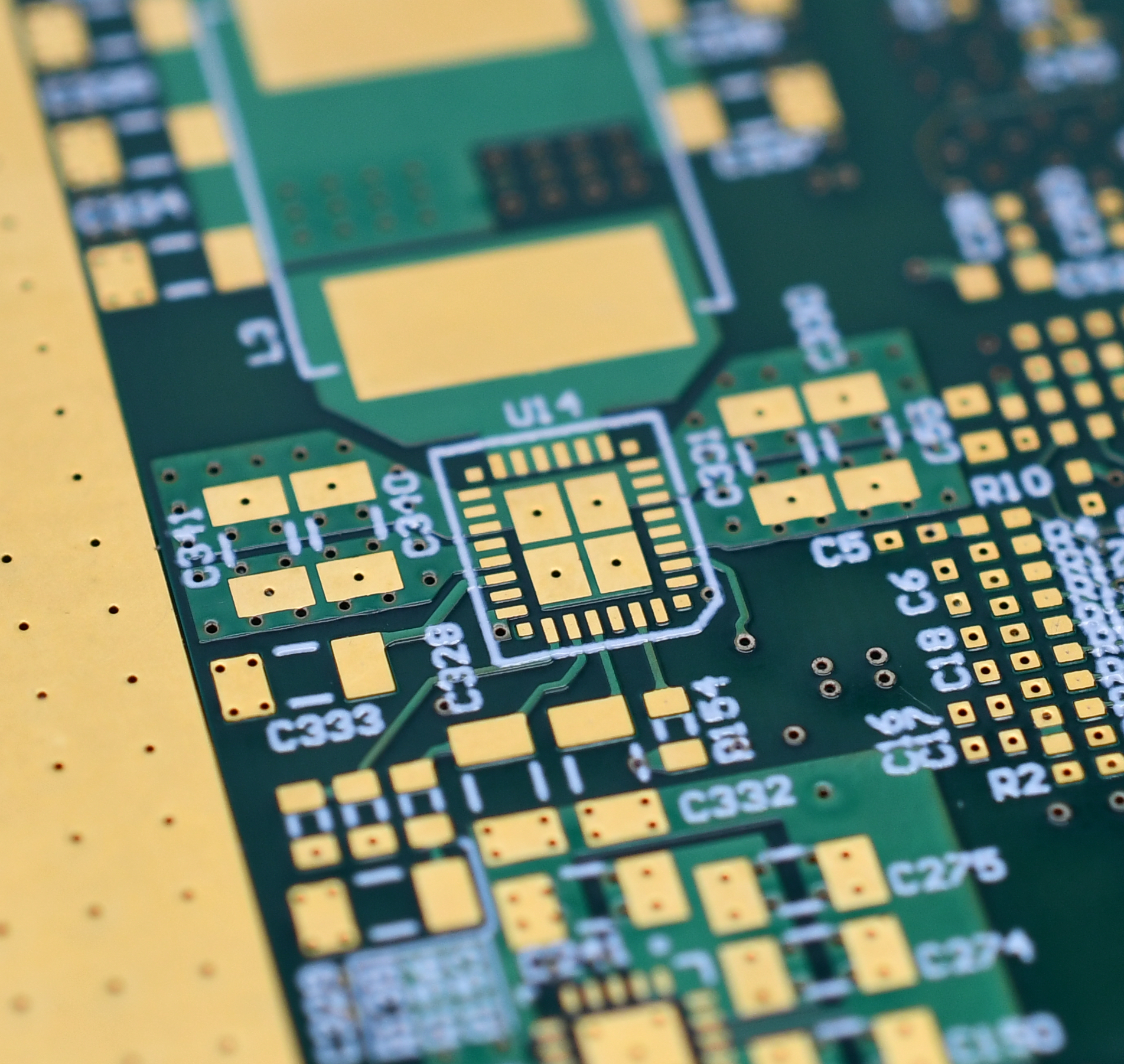

Miniaturization and large-scale integration have pushed the electronics industry to increase power and capabilities in Ball Grid Array BGA, Quad Flat No-Lead QFN devices. We specialize in restocking these devices with less than 30 defects per million.

How Do Circuit Boards Work

With the precision of today's process equipment, we can reliably install extremely small surface mount components as small as 0201 in (0603 mm) and as small as 01005 in (0402 mm).

The x-ray technology used at Vital Systems is capable of producing images that cannot be seen by inspectors. This is the integrity of any solder joint. Heat dissipation is critical for QFNs, and this technology provides just that critical information.

Automated Optical Inspection or AOI is the latest visual inspection technology in the industry. This 3D inspection system is extremely fast and accurate. This is how we test millions of solders and ensure the highest quality.

Once the PCB assembly is complete they are powered up for the first time, this is where they get their firmware. Some PCBAs will be tested to ensure that all components in the various circuits are functioning properly.

Custom Printed Circuit Board Pcb Assembly Services California, Usa

Vital Systems offers biased or unbiased ICT testing in the scheme. If necessary, this test verifies the normal operation of this circuit.

After the PCBA is fully assembled, these devices undergo a final full functional test. This test simulates how these units will perform in the field after deployment.

Customers require that every passive and active component be tested for correct device type, value, orientation and solder integrity. The military has always used advanced technology to conduct successful campaigns and protect our shores. Since the 20th century, this technology has included premium military and defense circuit boards.

Military and defense PCBs are often held to a higher standard than conventional PCBs because their role is so critical and they will be exposed to such harsh environments. Military grade PCBs are the toughest, most efficient and most reliable printed circuit boards on the market.

Pcb Manufacturing And Assembly

Military and defense PCBs can include PCBs for naval operations, aviation, general defense and even space applications. Because the applications of military PCBs are so varied, it is important to have access to a variety of PCB types to ensure that your military and defense PCBs are suitable for the electronics that use them.

These military printed circuit boards are often subjected to high pressure and stress, which means they will often require high temperature substrates such as heat resistant laminates, copper or aluminum. Military PCB manufacturers must produce PCBs that will resist heat-induced oxidation and dissipate heat efficiently in a low-weight design.

Rayming provides high-quality, durable, heat-resistant PCBs for a variety of military and defense applications. Rayming is ISO 9001:2008, UL and RoHS certified, so you can count on these PCBs to perform well in the harsh environments required for military equipment. We also manufacture various types of printed circuit boards for a wide range of military and defense applications.

If you have military or defense applications that require quality PCBs, find out why companies around the world trust Rayming in almost every major industry. Unlike many other PCB manufacturers, we also do assembly, so you don't have to waste time finding a good assembly material supplier and transporting your materials between locations. We take care of everything, which means you get your PCBs faster and your work can run more smoothly.

Printed Circuit Boards

Military drone range, laser range finder military, military range bags, military range targets, long range military radio, military radio range, military range finder, military long range binoculars, range rover military discount, military range rover, range of military drones, military range bag

0 Comments