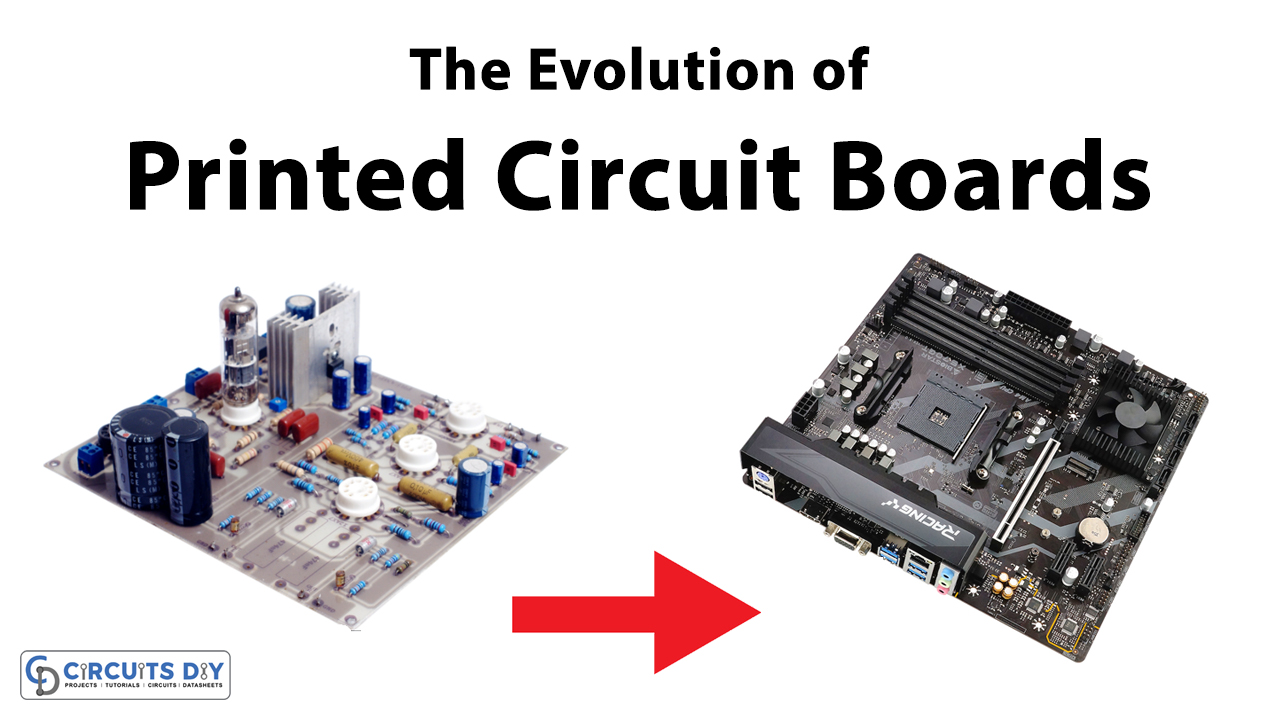

Military Pcb Manufacturer - The military has always incorporated modern technology to conduct operations and protect our coastline. Since the 20th century, this technology has included large-scale military and security printed circuit boards.

Military and defense PCBs are often held to a higher standard than ordinary PCBs because their work is very important and they will be trained in such extreme conditions. Military PCBare makes the strongest, most efficient and most reliable punch around the board. on the market.

Military Pcb Manufacturer

Military and defense PCBs can include screen printing for marine, aerospace, general defense and even aerospace applications. Because military PCB applications vary, it's important to have access to a variety of PCB types so you can be sure that military and defense PCBs will be compatible with the electronic devices they use.

Designing To Military Grade Electronics: Pcb Specifications With Altium Designer

These military circuits will often be subjected to high pressures and loads, which means they will need high temperature PCB-like laminates that are heat resistant, copper or aluminum. SojaPCB manufacturers must provide PCBs that are resistant to heat-induced oxidation and efficiently dissipate heat in a light-weight design.

The aerospace industry is one area that requires more robust PCBs than those required for conventional devices. Electronic components used in aircraft, rockets, satellites and control towers must be robust in extreme conditions. They are exposed to some minor conditions that will put more pressure on standard PCBs than they can handle. And if these basic elements fall apart, the result can be catastrophic.

Therefore, PCB manufacturers are very careful and use durable materials when it comes to space. Advances in printed circuit boards benefit the aerospace industry by making them safer and more efficient.

In space, electronics can be exposed to temperatures of up to 150 degrees Celsius, there is no air to transfer heat in space, so the only way to transfer heat is by radiation.

Pcbgogo Offers Topnotch Pcb Fabrication Services

Manufacturers use some hot laminate, copper and aluminum PCB substrates in aerospace PCBs to survive these extreme temperatures. Thermal compound is also often used to prevent heat transfer to other electronic components.

You can set the components about 20 thousandths of an inch from the top of the screen or use the space for easier heat dissipation. In an airplane, fans can be used to dissipate extra heat.

Electronics used in the aerospace industry can also be exposed to mechanical stresses such as shocks and vibrations.

In order for PCBs to withstand these types of conditions, manufacturers make changes to the board design every now and then. Some use pins that are pressed into the board to help hold the components in place, as opposed to soldering. In some cases, engineers connect the pins and solder for extra security.

Custom Rigid Flex Printed Circuit Boards Pfc Pcb Manufacturer

Some PCB fabrication techniques that are safer at high or low temperatures also have shock and vibration protection applications. Applying a warm surface to the screen can help reduce the impact of the transition. Leaving some space between the components and the surface of the board can also help the PCB stretch.

PCBs used in space must overcome a unique challenge. The higher levels of radiation in space can damage equipment if it is not suited to withstand its effects.

Manufacturers try to protect electronics from radiation by using different PCB materials. They are also usually smaller, so fewer particles are exposed to radiation. They also build reserves so that a single radiation event does not destroy the entire operation.

Antifuse technology, which creates permanent ways to conduct electricity between transistors, has been found to be more resistant to radiation. Other types of circuits are stronger by using smaller layers of material.

Does Your Project Need A Custom Pcb?

In an airplane, radio waves must be used for communication, so it is important that the signal is transmitted without being damaged in any way.

To ensure that the radio communication works properly, manufacturers need to place shields in important places on the PCB and sometimes use antennas. Creating very short transmission lines can help ensure accurate transmission of radio communications.

The most common development technologies in the current PCBA (Printed Circuit Board Assembly) industry are of two types:

Thru-Hole technology works on PCB assemblies that contain large components such as capacitors or coils that need to be assembled.

Designing With Circuitseal

It is called Surface Mount SMT. He usually works on small components like ICs (integrated circuits), things even smaller than the size of a pencil.

A surface mount assembly refers to a mounting system in which surface mount devices or surface mount devices (SMDs) are attached to a board with solder paste that acts as an adhesive to bond surface mount components to a surface. The general assembly process for surface mount consists of solder paste printing, fixed mounting, automatic inspection (AOI), PCB soldering, AOI or AXI, etc.

Developed in the early 1960s, skylight technology has been popular since the 1980s. So far, it can be concluded that most electronic products are assembled using SMT. The SMT access points are smaller in size and can be mounted on both sides of the board, so the surface mount assembly works better on larger and lower profile products. In addition, light weight and low cost are two main characteristics of future electronic products. Therefore, maintenance replacement therapy will be increasingly accepted in the industry.

Surface mount devices cover such a wide range of functions that it is impossible to list them one by one. But it is not a difficult task to summarize their characteristics, which will allow you to better understand the surface rock:

Amphenol Printed Circuits

In A quick guide. Unlike through-hole components with conductors, surface mounts or devices have short conductors, resulting in a strong electrical connection.

B. Small sizes. SMDs are much smaller than through-hole components, and some of them are even too small to be seen with the naked eye, such as package 01005. Smaller SMDs result in more board space savings.

C. Very reliable. SMDs rely on solder balls on the ground to select proper bonding and solder placement, making them well suited for board soldering, improving reliability and repeatability.

SMT is more affordable for smaller PCB sizes, higher density components and more board space. Due to the lack of need for drilled holes, SMT offers an inexpensive but short manufacturing time. In the PCBA process, the speed of SMT assembly can reach thousands or even tens of thousands of chips per hour, while through-hole assembly is less than a thousand chips. In addition, the gold bonding material through the rotary oven has higher quality and repeatability, and SMT has been proven to perform strongly when vibration occurs.

Looking For Advanced Military And Aerospace Pcb Assembly Supplier ?

Circuits are used every day and are essential to most electronics. However, our devices usually do not have to withstand extreme heat or radiation. When it comes to printed circuit boards for the aerospace industry, a lot has to be put up with.

Advances in control circuit design have enabled the development of the aerospace industry. Without space circuits that can handle the radiation, we may not be able to explore space or send satellites into Earth orbit. If the circuits used in helicopters cannot withstand shock and vibration, they can be damaged, resulting in a dangerous situation.

As the circuit industry continues to develop new ways to make PCBs stronger, stronger and safer, the aerospace industry will benefit as well. Space equipment will be able to use PCBs in an efficient manner, require frequent maintenance, and operate reliably and efficiently. Although circuits are only one part of the aerospace industry, they are important because they can have a huge impact on the industry. With the growing popularity of electronic products, companies must find ways to keep up with demand. They need to sell their products quickly and efficiently. This means that they are produced and distributed in the right way.

Therefore, they must look for ways to reduce costs and increase the speed of delivery. One way to do this is to use stores that offer military electronics at affordable prices.

Military Pcb Manufacturer

The biggest challenge these companies face is not knowing which stores offer the best deals on military electronics products. So they waste time and money trying different websites in hopes of getting a discount on their purchases. Unfortunately, this can lead them down a rabbit hole where they end up spending more money than necessary to buy cheap electronics from an unknown company with no guarantee that their purchase will be delivered on time when promised or even not enough!

If you're making military electronics, you need a PCB manufacturer that has experience producing this type of board. The design and manufacturing process of these products must meet certain standards. A military PCB manufacturer must have experience with a variety of layouts and materials and be fully trained and certified. And this is where Rayming technology comes in as a PCB manufacturer for military electronics.

In recent years, the military market has seen many changes. The military uses various types of electronic devices. Something for communication, something for security.

Military electronics are electronic

Hybrid Rf Pcb Manufacturer Process Hot Sale For Automotive

Military drone range, laser range finder military, military range bags, military range targets, long range military radio, military radio range, military range finder, military long range binoculars, range rover military discount, military range rover, range of military drones, military range bag

0 Comments